Engineering 6 Lab 1:

Concurrent Force Equilibrium in 3-D

Paul Agyiri, Aron Dobos

13 February 2005

Abstract

In this lab, the weight of a mass hanging in equilibrium from three cords was determined, as well as the friction coefficients of the three pulleys involved. From the collective class data, the average weight was determined to be 1077 grams, with an error of approximately ± 2.5%. The average friction coefficients for the pulleys 1, 2, and 3 were determined to be 0.208, 0.131, and 0.158, with standard deviations of 0.008, 0.004, and 0.003, respectively. The efficiencies of the three pulleys were calculated to be 96%, 97.5%, and 96.7%, respectively.

Procedure

Three pulleys were set up as shown in the sketch of the apparatus with an unknown weight being supported at the point where the three ropes that hung from each pulley met. This setup was done above a floor with and x-y grid on it. The values of three specific weights were recorded and these weights were hung on the pulleys, with one weight hanging from each pulley. The unknown weight was pulled down and slowly allowed to reach equilibrium position from the bottom (that is slowly allowed to come to rest). The x, y and z positions of the unknown weight were measured and recorded. Using the same set of weights, the unknown weight was raised up slightly and slowly guided downwards until it came to equilibrium again. The new x, y and z coordinates were measured and recorded. A diagram of the pulley-weight configuration is shown below in Figure 1.

Figure 1. Setup

Free Body Analysis

The displacement vectors from the junction coordinate to each of the three pulleys is calculated by subtracting the respective X, Y, and Z components of the junction from the pulley coordinates. The Z coordinate was adjusted to account for the radius of the pulley.

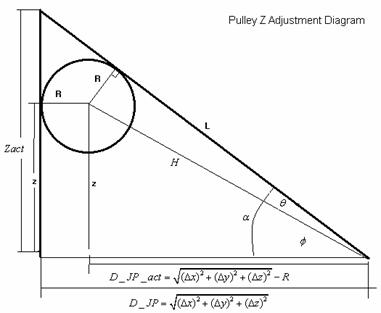

The first step in the free body analysis is to adjust for the actual Z coordinate using the known radius of the pulley. The actual distance from the junction to the pulley sheave in the X-Y plane is calculated using the equation below.

![]()

Given this distance, the angle phi can be calculated with the Pythagorean Theorem, as well as the hypotenuse H of the smaller right triangle. With H and R, the angles theta and alpha are determined to be

![]() ,

,

and Zact is given by

![]() .

.

To calculate the weight of the hanging object, it is assumed that the pulleys are frictionless and thus the weight at the end of each cord is equal to the tension in that cord. Given the adjusted three dimensional displacement vectors, the Z component of each cord tension can directly be determined by multiplying the cord tension by the normalized Z component vector. Summing the Z components of each of the three tensions gives the weight of the hanging objects, since the sum of the forces in the Z direction must be zero:

![]()

where ![]() is the normalized ith displacement

vector in the z direction.

is the normalized ith displacement

vector in the z direction.

An estimate for the actual weight is determined by averaging the weight from the ‘above’ run with the weight obtained from the below run.

![]()

Given the average mass, the friction can be calculated for approaching equilibrium from above and below.

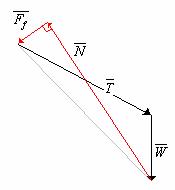

Diagram For Calculating Friction Force

Taking the difference between AverageMass and MassAbove (or MassBelow) gives the difference in the Z-component of the tension between the actual and friction-less tension. The actual tension is thus given by

![]()

The friction force is determined by summing torques around the pulley center.

![]()

The normal force vector to the friction force from the weight junction is readily obtained by the Pythagorean Theorem.

![]()

The coefficient of friction and the pulley efficiency are given by the following relationships below.

![]()

Results

The data and results obtained for each ‘above’ and ‘below’ run is included below in Table 1. The results were calculated automatically by the runall.m and calcforces.m MATLAB scripts.

Table 1. Collective Class Weight, Above/Below XYZ

Data with Calculated Results for each run.

|

Run |

Wt 1 |

Wt 2 |

Wt 3 |

AX |

AY |

AZ |

BX |

BY |

BZ |

Mass |

P1 Mu |

P2 Mu |

P2 Mu |

|

1 |

683 |

748 |

729 |

-1 |

38.3 |

78.4 |

-1.9 |

39.5 |

75 |

1070.02 |

0.1193 |

0.0869 |

0.1177 |

|

2 |

894 |

948 |

488 |

-16 |

4.2 |

79.8 |

-17.1 |

4.8 |

77.4 |

1162.04 |

0.091 |

0.0461 |

0.1433 |

|

3 |

604 |

552 |

785 |

5.6 |

29.4 |

77.2 |

3.5 |

30.6 |

72.2 |

1052.51 |

0.1671 |

0.1398 |

0.1453 |

|

4 |

763 |

749 |

995 |

7.5 |

26.8 |

88.5 |

6.1 |

27.9 |

86.6 |

1075.29 |

0.0612 |

0.0452 |

0.0573 |

|

5 |

328 |

878 |

655 |

7.5 |

78 |

65.8 |

7 |

77 |

60.2 |

1098.33 |

0.2813 |

0.1239 |

0.1491 |

|

6 |

432 |

692 |

787 |

12.2 |

41 |

72 |

10.2 |

44.6 |

67.6 |

1065.79 |

0.1587 |

0.0886 |

0.1021 |

|

7 |

627 |

512 |

550 |

-7.4 |

34.6 |

64.1 |

-8.9 |

35.5 |

57.4 |

1054.49 |

0.1845 |

0.1775 |

0.2074 |

|

8 |

456 |

693 |

814 |

12 |

39.1 |

74.8 |

10.5 |

40.5 |

70.1 |

1066.08 |

0.1921 |

0.1091 |

0.1274 |

|

9 |

379 |

308 |

875 |

24.6 |

12.5 |

76 |

21.5 |

15.8 |

67.6 |

1059.44 |

0.1847 |

0.1733 |

0.1119 |

|

10 |

379 |

705 |

494 |

2.1 |

69.4 |

49.4 |

0.8 |

70 |

40.3 |

1081.26 |

0.3005 |

0.1694 |

0.2357 |

|

11 |

503 |

576 |

624 |

1.6 |

41.1 |

61.5 |

0.8 |

41.8 |

55.8 |

1066.87 |

0.1817 |

0.1367 |

0.1545 |

|

12 |

433 |

482 |

567 |

3.1 |

40.8 |

48 |

1.4 |

41.4 |

34.8 |

1064.36 |

0.3506 |

0.2748 |

0.275 |

|

13 |

324 |

848 |

416 |

0.6 |

96.6 |

56.5 |

0.1 |

94.8 |

46.6 |

1096.19 |

0.3077 |

0.1518 |

0.2428 |

|

14 |

324 |

744 |

867 |

18.3 |

43.5 |

76.3 |

16.8 |

46.4 |

68.6 |

1052.91 |

0.4456 |

0.1687 |

0.1945 |

|

15 |

703 |

903 |

596 |

-6.3 |

57.4 |

75.4 |

-7.5 |

58.3 |

72.6 |

1090.55 |

0.0955 |

0.0707 |

0.1118 |

Table 2. Summary of Pulley Friction Coefficients, Standard

Deviations, and Efficiencies.

|

Pulley |

Mu |

StdDev |

Efficiency

(%) |

|

1 |

0.2081 |

0.008 |

96.05 |

|

2 |

0.1308 |

0.0043 |

97.54 |

|

3 |

0.1584 |

0.0033 |

96.77 |

Table 3. Final Mass and Error Estimates

|

Object Mass |

Approx. Error |

|

1077.1 |

~ 4 - 6% |

Error Considerations

We can calculate the approximate error in the weight of the hanging mass by considering the difference between the weight obtained from ‘below’ runs and ‘above’ runs, and comparing them to the average weight. This gives an estimate of the spread of the weight values obtained, and clearly includes the uncertainties resulting from the friction in the pulleys.

Error in the weight due to friction =

(weight from below – weight from above)/2

average weight

(1128.4 –

1078.7)/2

(1128.4 + 1078.7)/2

= 2.25%

Another approximate measure of the error can be obtained from the sum of forces in the X and Y directions. Ideally, these forces should sum to 0, since the hanging mass is in equilibrium. Taking the root mean square (RMS) of the X and Y tension sums gives an estimate of the total XY error, and dividing this error value by the Z tension results in a value that represents the total error in the measurement of the Z tension. Averaging all of these error values together gives an error of approximately 7 % from all the ‘above’ and ‘below’ runs. This error is much greater than the error estimate obtained from the much simpler calculation described above. A possible reason is that in this case, the error in each individual force equilibrium calculation is a greater percentage, whereas when all of the ‘above’ and ‘below’ runs are averaged, the result evens out and represents a smaller spread of values, even though the actual error invovled in calculating the final averages might have been greater.

If the total spread of the ‘above’ and ‘below’ runs is considered instead of just the difference between the mean weight value, the basic error calculation gives 2*2.25 = 4.5 % error, which seems more reasonable next to the XY error calculation. Given these various methods of calculating error, it is probably safe to conclude that the final error in the weight of the hanging mass is approximately between 4 and 6 percent.

Discussion

The frictional forces in the pulleys produced a difference in the unknown weight which was calculated to be a percentage error of approximately 4-6%. This is a relatively small error, and as a result it is probably safe to assume for most applications that the pulley is indeed frictionless. If more precision is required in obtaining weight values of hanging masses, the friction in the pulleys probably should not be neglected. Knowing how the friction affects tests reaching equilibrium from above and from below, it should be enough to do both tests and average the values, as the frictional effects should cancel out and give an accurate value for the weight of the hanging mass.

MATLAB CODE

runall.m

% runall.m

% Aron

Dobos, Spring 2006

%

% Calculates all the masses, pulley frictions, and average XY

errors,

% and

averages them. The variable AllData must be in the workspace.

% It is just a big table contain all the data points in the

following

%

format. The table can have

as many rows as needed.

%

% [

Weights ] [ FromAboveXYZ

] [ FromBelowXYZ

]

%

% 763

749 995 7.5

26.8 88.5 6.1

27.9 86.6

% 328

878 655 7.5

78 65.8 7

77 60.2

% 432

692 787 12.2

41 72 10.2

44.6 67.6

% 627

512 550 -7.4

34.6 64.1 -8.9

35.5 57.4

% 456

693 814 12

39.1 74.8 10.5

40.5 70.1

% 379

308 875 24.6

12.5 76 21.5

15.8 67.6

%

[M N] = size(AllData);

fp = fopen('mresults.txt', 'w');

Weights = zeros(M, 3);

Above = zeros(M, 3);

Below = zeros(M, 3);

XYError = 0;

AllMus = zeros(M, 3);

AvgMus = zeros(3, 1);

AvgEff = zeros(3, 1);

MuStdDev = zeros(3,1);

AverageMass = 0;

AvgFrictionForce = 0;

for I=1:M

Weights(I,:) = AllData(I, 1:3) / 1000;

% weights in kilograms

Above(I,:) = AllData(I, 4:6) / 39.3700787; %

locations in meters

Below(I,:) = AllData(I, 7:9) / 39.3700787; %

locations in meters

% calculate all values for the I-th run using the calcforces

function

calcs

= calcforces(Weights(I,:), Above(I,:), Below(I,:));

for K=1:3

AllMus(M,K) = calcs.PulleyMuAvg(K);

AvgMus(K) = AvgMus(K) + calcs.PulleyMuAvg(K);

AvgEff(K) = AvgEff(K) + calcs.PulleyEffAvg(K);

end

% average the friction forces

AvgFrictionForce

= AvgFrictionForce + calcs.AvgFriction;

% average the masses

AverageMass = AverageMass + calcs.ActualMass;

% average the RMS errors from 0,0 for the XY coordinate tensions

XYError = XYError + calcs.AvgErrXY;

fprintf(fp, '%d\t%d\t%d\t', Weights(I,1), Weights(I,2), Weights(I,3));

fprintf(fp, '%.1f\t%.1f\t%.1f\t', Above(I,1),

Above(I,2), Above(I,3));

fprintf(fp, '%.1f\t%.1f\t%.1f\t', Below(I,1),

Below(I,2), Below(I,3));

fprintf(fp, '%.2f\t%.4f\t%.4f\t%.4f\n', calcs.ActualMass, calcs.PulleyMuAvg(1),

calcs.PulleyMuAvg(2), calcs.PulleyMuAvg(3));

end

AvgFrictionForce = AvgFrictionForce

/ M;

AverageMass = AverageMass / M;

XYError = XYError / M;

% average

all the frictions and efficiencies for each pulley

for K=1:3,

AvgMus(K) = AvgMus(K) / M;

AvgEff(K) = AvgEff(K) / M;

end

%

calculate the standard deviations for the pulley frictions

for K=1:3

fsum

= 0;

for I=1:M

fsum

= ( AllMus(M,K) - AvgMus(K)

)^2;

end

MuStdDev(K) = sqrt(fsum)

/ (M-1);

end

fclose(fp);

% display the results.

AverageMass

XYError

AvgMus

MuStdDev

AvgEff

AvgFrictionForce

calcforces.m

function [ret] = calcforces(hanging_weights, above_data, below_data)

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

% calcforces.m

% Matlab script to calculate tensions, weights, and frictions

% Units are inches, grams

% Aron

Dobos, Spring 2005

%

% PFromAbove = [7.5 78 65.8];

% PFromBelow = [7 77 60.2];

%

% usage: calcforces(hanging_weights[1x3], above_data[1x3],

below_data[1x3])

%

% Example:

% > PFromAbove = [7.5 78 65.8];

% > PFromBelow = [7 77 60.2];

% >

Weights = [328 878 655];

% > calcforces(Weights,

PFromAbove, PFromBelow);

% ABOVE:

tension 1: Alpha=28.374703 degrees, Z=120.704820

% ABOVE:

tension 2: Alpha=40.355489 degrees, Z=120.968397

% ABOVE:

tension 3: Alpha=32.473082 degrees, Z=120.778002

% Mass for

run ABOVE=1091.953522 grams

% BELOW:

tension 1: Alpha=31.051536 degrees, Z=120.750897

% BELOW:

tension 2: Alpha=42.729991 degrees, Z=121.042040

% BELOW:

tension 3: Alpha=35.270283 degrees, Z=120.837251

% Mass for

run BELOW=1161.211849 grams

% ABOVE

Pulley 1 Mu=0.269096

% ABOVE

Pulley 2 Mu=0.122617

% ABOVE

Pulley 3 Mu=0.145532

% BELOW

Pulley 1 Mu=0.286309

% BELOW

Pulley 2 Mu=0.126376

% BELOW

Pulley 3 Mu=0.152947

%

% ans =

%

% AverageMass:

1.1266e+003

% PulleyMuAvg:

[0.2777 0.1245 0.1492]

% data: [1x2 struct]

%

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

Weights = hanging_weights;

data(1).Junction = above_data;

data(1).RunName = 'ABOVE';

data(2).Junction = below_data;

data(2).RunName = 'BELOW';

% Define

the known data points

SnapWeight = 9 / 1000; % in kilograms

JunctionSnapWeight = 13 / 1000; % in

kilograms

% pulley

locations in meters

P1 = [-60 0 119]

/ 39.3700787;

P2 = [0 144 119]

/ 39.3700787;

P3 = [48 0 119]

/ 39.3700787;

PRadius = 1.5 / 39.3700787; % pulley radius

AxleRadius = 0.1875 / 39.3700787; % axle

radius

Pullies = [ P1; P2; P3 ];

Weights =

Weights + SnapWeight; % add the snap weight

% get the forces (frictionless cable tensions) in newtons

WeightForces = Weights * 9.81;

ret.AverageMass = 0;

ret.AvgErrXY = 0;

% iterate

through the 'above' run and the 'below' run

for D=1:2

% initialize

some variables for the data set.

data(D).Displace =

zeros(3,3);

data(D).Normalized

= zeros(3, 3);

data(D).D_JP =

zeros(3,1);

data(D).H =

zeros(3,1);

data(D).Zact = zeros(3,1);

data(D).D_JP_act = zeros(3,1);

data(D).Alpha =

zeros(3,1);

data(D).Phi =

zeros(3,1);

data(D).Theta =

zeros(3,1);

for I=1:3

% calculate the displacement

vectors for this run

data(D).Displace(I,:)

= Pullies(I,:) - data(D).Junction;

% calculate the distance from the

junction to the pulley

data(D).D_JP(I) = sqrt(

data(D).Displace(I,1)^2 + data(D).Displace(I,2)^2 );

% adjust the distance to get the

actual distance from the junction

% to the center of the pulley

sheave

data(D).D_JP_act(I) = data(D).D_JP(I) - PRadius;

% calculate the hypotenuse of the the triangle whose base is the

% distance from J to the pulley

sheave and height is the delta Z.

data(D).H(I) = sqrt(

data(D).D_JP_act(I)^2 + data(D).Displace(I,3)^2 );

% calculate the Phi angle in the

triangle (See drawing)

data(D).Phi(I)

= atan2(data(D).Displace(I,3), data(D).D_JP_act(I)) *

180/pi;

% likewise calculate theta for the

smaller triangle

data(D).Theta(I)

= asin( PRadius /

data(D).H(I) ) * 180/pi;

% determine alpha which is the

actual angle the cord makes with the

% horizontal axis

data(D).Alpha(I)

= data(D).Phi(I) + data(D).Theta(I);

% from alpha calculate the actual

Z

data(D).Zact(I) = data(D).D_JP_act(I)*tan(data(D).Alpha(I)*pi/180);

disp( sprintf('%s: tension %d: Alpha=%f degrees, Z=%f', data(D).RunName, I, data(D).Alpha(I), data(D).Zact(I)+data(D).Junction(3)));

% update the displacement vector

with the actual Z coordinate

data(D).Displace(I,3)

= data(D).Zact(I);

% normalize to obtain unit vectors

for the displacements

data(D).Normalized(I,:) =

data(D).Displace(I,:) / norm(data(D).Displace(I,:));

end

data(D).TSumX = 0;

data(D).TSumY = 0;

data(D).TSumZ = 0;

% sum the force components in the X Y and Z directions

assuming no

%

friction.

for I=1:3

data(D).TSumX = data(D).TSumX + WeightForces(I)*data(D).Normalized(I,1);

data(D).TSumY = data(D).TSumY + WeightForces(I)*data(D).Normalized(I,2);

data(D).TSumZ = data(D).TSumZ + WeightForces(I)*data(D).Normalized(I,3);

end

% take

the RMS (root-mean-square) of the X and Y sums (which should be

% zero) to get an estimate of the

error

data(D).ErrXY = sqrt(data(D).TSumX^2 +

data(D).TSumY^2);

% now take obtain the percentage

error from the Z sum to get an idea of

% how off the Z sum could be

data(D).ErrXYPercentOfZ = data(D).ErrXY /

data(D).TSumZ * 100;

disp(sprintf('XYZ sums: %f %f %f (RMS %f err %f)', data(D).TSumX, data(D).TSumY, data(D).TSumZ, data(D).ErrXY, data(D).ErrXYPercentOfZ));

ret.AvgErrXY = ret.AvgErrXY + data(D).ErrXYPercentOfZ;

% the mass is just the sum of the

Z components of the tensions

% divided by gravitational

acceleration

data(D).Mass =

data(D).TSumZ / 9.81;

ret.AverageMass =

ret.AverageMass + data(D).Mass;

disp(sprintf('Mass for run

%s=%f grams', data(D).RunName, data(D).TSumZ));

end

%

determine the average mass

ret.AverageMass = ret.AverageMass

/ 2;

ret.AvgErrXY = ret.AvgErrXY

/ 2;

% now

calculate all the pulley frictions from both above and below runs

for D=1:2

% initialize

the friction variables

data(D).Frictions

= zeros(3,1);

data(D).Normals = zeros(3,1);

data(D).PulleyMu = zeros(3,1);

data(D).Tensions =

zeros(3,1);

data(D).Efficiency

= zeros(3,1);

data(D).MassDiff = abs(data(D).Mass - ret.AverageMass);

for I=1:3

% calculate the actual tension in

the cord by using the mass

% difference from the run and the

average

data(D).Tensions(I)

= WeightForces(I) - 9.81*data(D).MassDiff

* data(D).Normalized(I,3);

% determine the friction force by

summing torques around the pulley

% wheel, accounting for the sheave

radius and outer radius

data(D).Frictions(I)

= 9.81*data(D).MassDiff * data(D).Normalized(I,3) * PRadius / AxleRadius;

% calculate the magnitude of the

sheave normal vector by

% the pythagorean theorem

data(D).Normals(I)

= sqrt( (data(D).Tensions(I)*data(D).Normalized(I,3)

+ WeightForces(I))^2 - data(D).Frictions(I)^2);

% determine Mu

= mag(F)

/ mag(N)

data(D).PulleyMu(I) = data(D).Frictions(I) / data(D).Normals(I);

% determine the efficiency of each

pulley

data(D).Efficiency(I) = 1 - data(D).MassDiff*9.81 * data(D).Normalized(I,3) / ((WeightForces(I)+data(D).Tensions(I))/2);

disp(sprintf('%s Pulley %d Mu=%f Eff=%f Friction=%f', data(D).RunName,

I, data(D).PulleyMu(I), data(D).Efficiency(I),

data(D).Frictions(I) ));

end

end

% average

the mu values for each pulley resulting from the

% above

and below runs

ret.AvgFriction = 0;

for I=1:3

ret.PulleyMuAvg(I) = 0;

ret.PulleyEffAvg(I) = 0;

for D=1:2

ret.PulleyMuAvg(I) = ret.PulleyMuAvg(I) +

data(D).PulleyMu(I);

ret.PulleyEffAvg(I) = ret.PulleyEffAvg(I) +

data(D).Efficiency(I);

ret.AvgFriction

= ret.AvgFriction + data(D).Frictions(I);

end

ret.PulleyMuAvg(I) = ret.PulleyMuAvg(I) / 2;

ret.PulleyEffAvg(I) = ret.PulleyEffAvg(I) / 2;

end

ret.AvgFriction = ret.AvgFriction

/ 6;

% subtract

the known snap weight from the averaged mass

ret.ActualMass = ret.AverageMass

- JunctionSnapWeight;

% return all calculated data values

ret.data = data;